Engineering & CAD Services

Reverse engineering and DFM-optimized solutions

We provide end-to-end technical support for manufacturers, transforming complex 3D scans into production-ready geometry.

Ready to discuss your technical specifications?

Reverse Engineering

Reconstruction from 3D Scan Data

We bridge the gap between physical objects and digital models. By transforming raw, unorganized mesh data into clean, feature-based CAD models, we provide you with editable files that maintain the design intent and mechanical integrity of the original part.

- Mesh-to-Solid Conversion

- Accuracy Verification

- Geometric Reconstruction

- Legacy Part Support

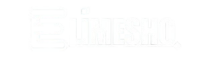

Modelling for 3D Printing

Additive Manufacturing Optimization

Designing for 3D printing requires more than just a 3D model; it requires an understanding of layer adhesion, support structures, and material properties. We optimize your geometry to ensure high success rates and functional performance.

- Print-Ready Geometry

- Support Reduction

- Mechanical Clearances

Functional Design & Prototyping

Concept Development & Mechanical Validation

We take your rough ideas or sketches and turn them into functional mechanical designs. Our focus is on solving engineering challenges early in the process, ensuring your prototype behaves exactly like the final manufactured product.

- Mechanism Design

- Assembly Logic

- Material Selection

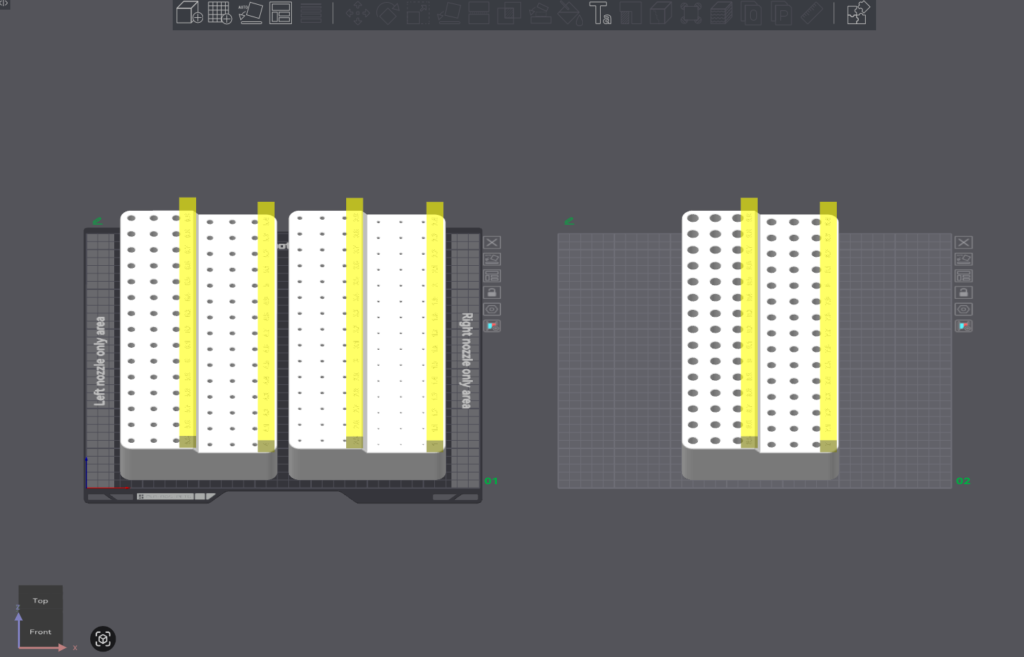

Product Concept Visualization

Digital Twin & High-Quality Rendering

Visualize your product before a single cent is spent on tooling. We create precise digital twins and high-quality visuals that allow you to present your design to stakeholders, investors, or customers with total confidence.

- Photorealistic Rendering

- Cross-Sectional Analysis

- Design Refinement

Assembly & Component Design

Complex Multi-Part System Engineering

We specialize in designing intricate assemblies where multiple parts must interact perfectly. By simulating the fit and function of every component, we eliminate costly interference issues before you order a single part.

- Interference Detection

- Tolerance Stack-up Analysis

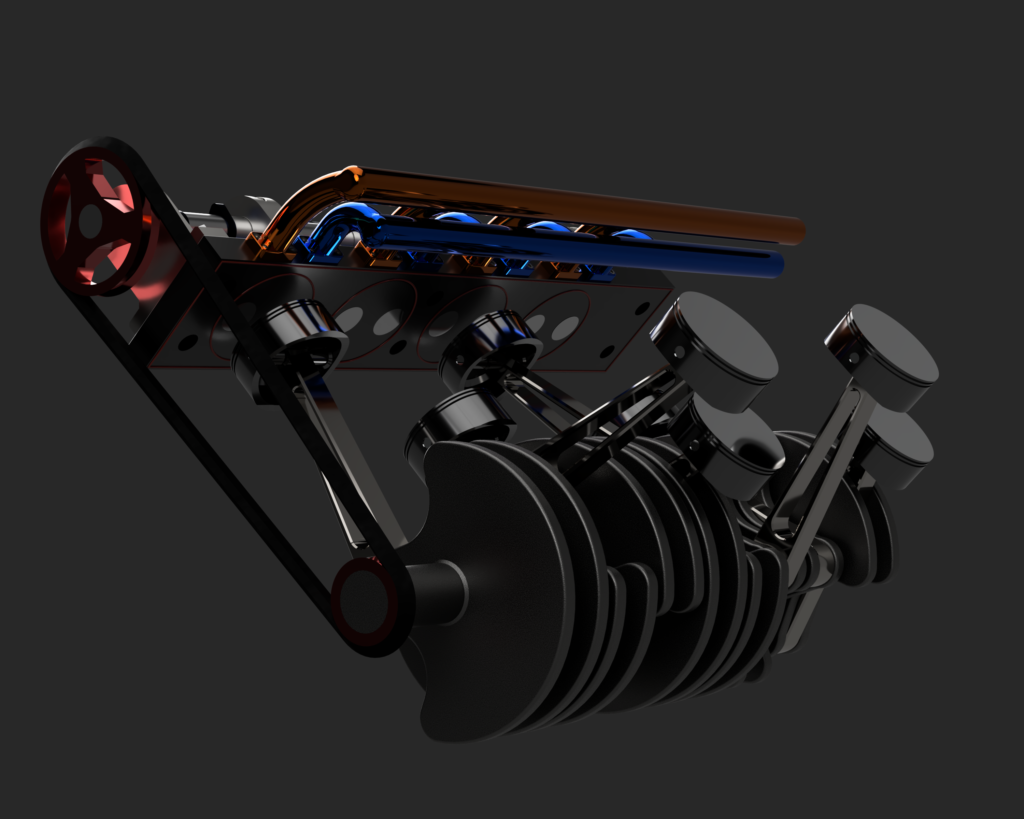

Model Review & Optimization

Design for Manufacturing (DFM)

A beautiful design is useless if it can’t be manufactured efficiently. We review your existing CAD files to identify manufacturing “red flags,” helping you reduce production costs and lead times by optimizing for CNC, molding, or casting.

- Tooling Accessibility

- Wall Thickness Uniformity

- File Cleanup

Technology Stack

Our 3 Steps Process

Analysis

We review your scans, sketches, or parts to define exactly what needs to be built.

Modeling

We build the digital parts using industry-standard CAD software, ensuring they are ready for production.

Delivery

We verify the dimensions and send you the final files, optimized for your specific manufacturing method.

Let's talk about your project

Whether you have a solid idea, a rough sketch, or just a part that needs fixing, we’re here to help you figure out the best way to build it. Send over what you have, and we can look at the next steps together.